ASTM A216 WCB Chemical Composition and Mechanical Properties

ASTM A216 specifies the chemical composition and mechanical properties of ASTM A216 WCB.

ASTM A216 WCB is carbon steel casting intended for use in high temperature service. WCB has good mechanical properties and weldability, which are achieved through a combination of high carbon content and careful control of impurities. A216 WCB is the common body material for valves.

A216 WCB Equivalent and Application

| ASTM Material | Material Group | Material Type | Forging Equivalent | UNS | DIN | DIN W.No | Application |

| A216-WCB | Carbon Steel | C-Mn-Fe | ASTM A105N | K03504 | C22.8 | 1.0460 | General non-corrosive service, -20°F(-29ºC) to 800°(425ºC) |

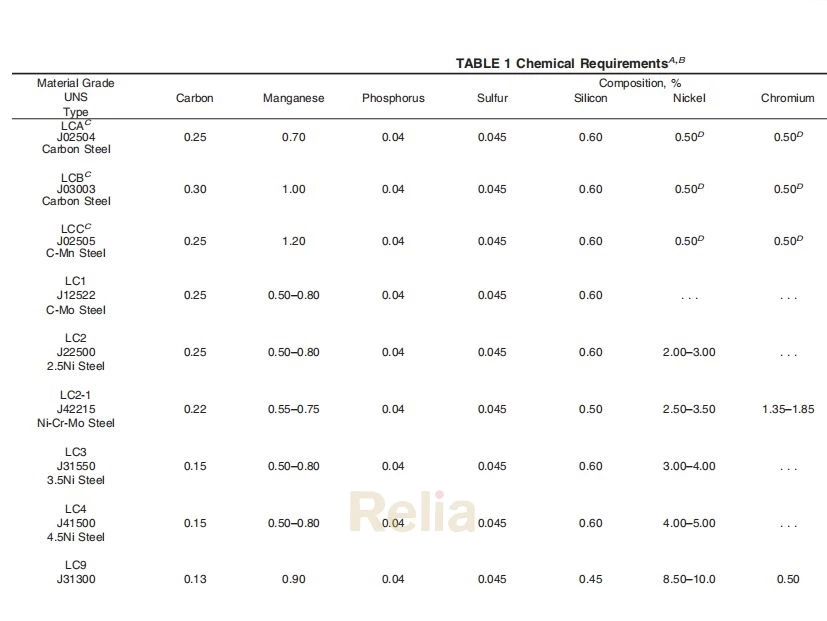

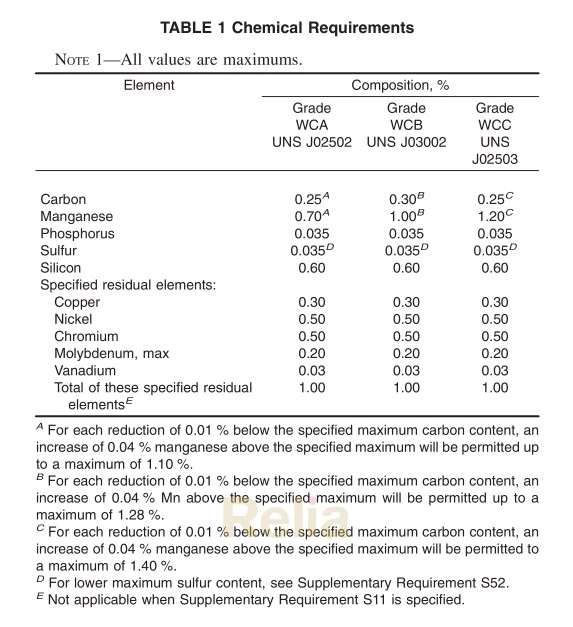

A216 WCB Chemical Composition (%)

All Value are maximum

| C | Mn | Si | S | P | Cr | Ni | Mo | Cu | V |

| 0.3 | 1 | 0.6 | 0.035 | 0.035 | 0.5 | 0.5 | 0.2 | 0.3 | 0.03 |

Note:

- For each reduction of 0.01 % below the specified maximum carbon content, an increase of 0.04 % Mn above the specified maximum will be permitted up to a maximum of 1.28 %.

- For each reduction of 0.01 % below the specified maximum carbon content, an increase of 0.04 % manganese above the specified maximum will be permitted to a maximum of 1.40 %.

- For lower maximum sulfur content, see Supplementary Requirement S52.

- Not applicable when Supplementary Requirement S11 is specified.

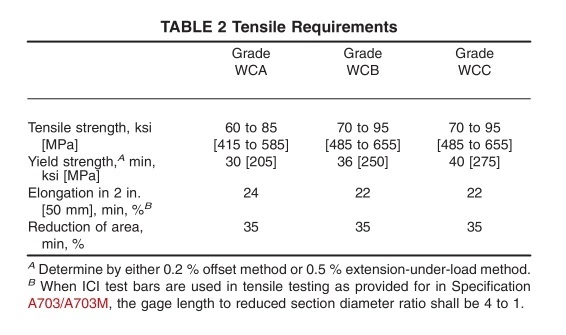

A216 WCB Mechanical Properties

All Value are miximum except Tensile Strength

| Tensile Strength (MPa) | Yield Strength(MPa) | Elongation in 2 in.(%) | Reduction of Area (%) |

| 485-655 | 250 | 22 | 35 |

Note:

- Determine by either 0.2 % offset method or 0.5 % extension-under-load method. When ICI test bars are used in tensile testing as provided for in Specification

- A703/A703M, the gage length to reduced section diameter ratio shall be 4 to 1.

ASTM A216 Specifications

A216 WCB Working Pressure, Temperature Rating (ASME B16.34)

Standard Class

| Temperaiure,℃ | Working Pressures by Class, bar | ||||||

| 150 | 300 | 600 | 900 | 1500 | 2500 | 4500 | |

| -29 to 38 | 19.6 | 51.1 | 102.1 | 153.2 | 255.3 | 425.5 | 765.9 |

| 50 | 19.2 | 50.1 | 100.2 | 150.4 | 250.6 | 417.7 | 751.9 |

| 100 | 17.7 | 46.6 | 93.2 | 139.8 | 233.0 | 388.3 | 699.0 |

| 150 | 15.8 | 45.1 | 90.2 | 135.2 | 225.4 | 375.6 | 676.1 |

| 200 | 13.8 | 43.8 | 87.6 | 131.4 | 219.0 | 365.0 | 657.0 |

| 250 | 12.1 | 41.9 | 83.9 | 125.8 | 209.7 | 349.5 | 629.1 |

| 300 | 10.2 | 39.8 | 79.6 | 119.5 | 199.1 | 331.8 | 597.3 |

| 325 | 9.3 | 38.7 | 77.4 | 116.1 | 193.6 | 322.6 | 580.7 |

| 350 | 8.4 | 37.6 | 75.1 | 112.7 | 187.8 | 313.0 | 563.5 |

| 375 | 7.4 | 36.4 | 72.7 | 109.1 | 181.8 | 303.1 | 545.5 |

| 400 | 6.5 | 34.7 | 69.4 | 104.2 | 173.6 | 289.3 | S20.8 |

| 425 | 5.5 | 28.8 | 57.5 | 86.3 | 143.8 | 239.7 | 431.5 |

| 450 | 4.6 | 23.0 | 46.0 | 69.0 | 115.0 | 191.7 | 345.1 |

| 475 | 3.7 | 17.4 | 34.9 | 52.3 | 87.2 | 145.3 | 261.5 |

| 500 | 2.8 | 11.8 | 23.5 | 35.3 | 58.8 | 97.9 | 176.3 |

| 538 | 1.4 | 5.9 | 11.8 | 17.7 | 29.5 | 49.2 | 88.6 |

NOTES:

- Upon prolonged exposure to temperatures above 425°C, the carbide phase of steel may be converted to graphite. Permissible, but not recommended for prolonged usage above 425°C.

- Only killed steel shall be used above 455°C.

- Not to be used over 370°C.

- Not to be used over 455°C.

- Not to be used over 260°C.

- Not to be used over 345°C.