ASTM A276 Chemical Composition, Mechanical Properties

ASTM A276 specifies the chemical composition and mechanical properties of ASTM A276 Alloy 20, 904L, XM-19 etc.

ASTM A276 covers hot-finished or cold-finished bars except bars for reforging (Note 1). It includes rounds, squares, and hexagons, and hot-rolled or extruded shapes, such as angles, tees, and channels in the more commonly used types

of stainless steels. The free-machining types (Note 2) for general corrosion resistance and high-temperature service are

covered in a separate specification.

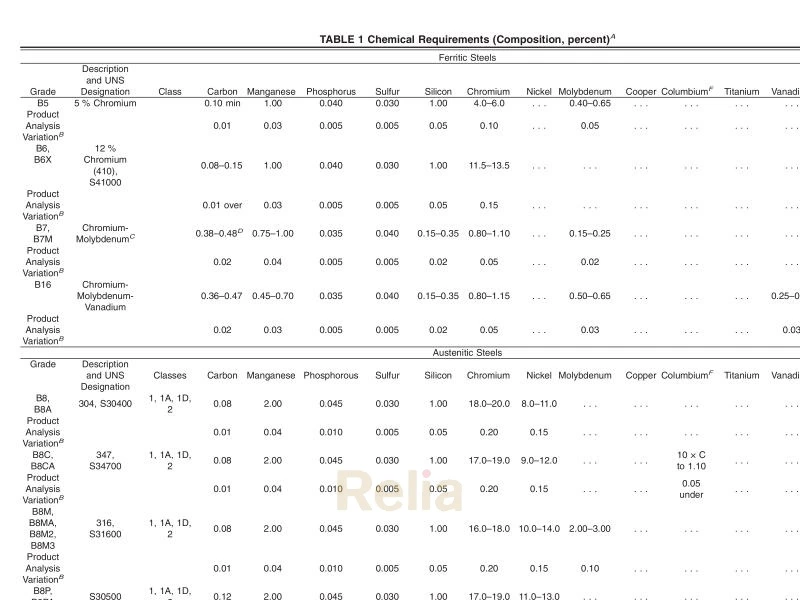

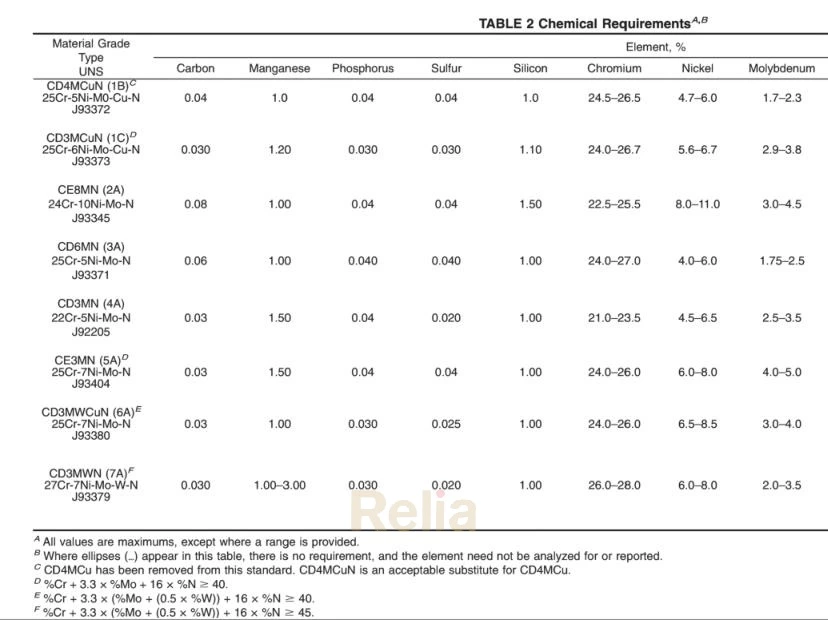

Chemical CompositionA

| DesignationB | Type | Carbon | Manganese | Phosphorus | Sulfur | Silicon | Chromium | Nickel | Molybdenum | Nitrogen | Other Elementst |

| Austenitic Grades | |||||||||||

| N08020 | Alloy 20 | 0.07 | 2.00 | 0.045 | 0.035 | 1.00 | 19.0-21.0 | 32.0-38.0 | 2.00-3.00 | ... | Cu 3.0-4.0 Nb 8 x C min.; 1.00 max |

| N08367 | ... | 0.030 | 2.00 | 0.040 | 0.030 | 1.00 | 20.0-22.0 | 23.5-25.5 | 6.0-7.0 | 0.18-0.25 | Cu: 0.75 |

| N08700 | ... | 0.04 | 2.00 | 0.040 | 0.030 | 1.00 | 19.0-23.0 | 24.0-26.0 | 4.3-5.0 | ... | Cu: 0.50 Cb: 8 x C min 0.40 max |

| N08800 | 800 | 0.10 | 1.50 | 0.045 | 0.015 | 1.00 | 19.0-23.0 | 30.0-35.0 | ... | ... | FeJ : 39.5 min. Cu: 0.75 Al: 0.15-0.60 Ti: 0.15-0.60 |

| N08810 | 800H | 0.05-0.10 | 1.50 | 0.045 | 0.015 | 1.00 | 19.0-23.0 | 30.0-35.0 | ... | ... | FeJ :39.5 min. Cu: 0.75 Al: 0.15-0.60 Ti: 0.15-0.60 |

| N08811 | ... | 0.06-0.10 | 1.50 | 0.045 | 0.015 | 1.00 | 19.0-23.0 | 30.0-35.0 | ... | ... | FeJ : 39.5 min. Cu: 0.75 AlK : 0.25-0.60 TiK : 0.25-0.60 |

| N08904 | 904L | 0.020 | 2.00 | 0.045 | 0.035 | 1.00 | 19.0-23.0 | 23.0-28.0 | 4.0-5.0 | 0.10 | Cu: 1.0-2.0 |

| N08925 | ... | 0.020 | 1.00 | 0.045 | 0.030 | 0.50 | 19.0-21.0 | 24.0-26.0 | 6.0-7.0 | 0.10-0.20 | Cu: 0.80-1.50 |

| N08926 | ... | 0.020 | 2.00 | 0.030 | 0.015 | 0.50 | 19.0-21.0 | 24.0-26.0 | 6.0-7.0 | 0.15-0.25 | Cu: 0.50-1.50 |

| S20100 | 201 | 0.15 | 5.5-7.5 | 0.060 | 0.030 | 1.00 | 16.0-18.0 | 3.5-5.5 | ... | 0.25 | ... |

| S20161 | ... | 0.15 | 4.0-6.0 | 0.045 | 0.030 | 3.0-4.0 | 15.0-18.0 | 4.0-6.0 | ... | 0.08-0.20 | ... |

| S20162 | ... | 0.15 | 4.0-8.0 | 0.040 | 0.040 | 2.5-4.5 | 16.5-21.0 | 6.0-10.0 | 0.50-2.50 | 0.05-0.25 | ... |

| S20200 | 202 | 0.15 | 7.5-10.0 | 0.060 | 0.030 | 1.00 | 17.0-19.0 | 4.0-6.0 | 0.25 | ||

Note:

A. Maximum, unless range or minimum is indicated. Where ellipses (. . .) appear in this table, there is no requirement and the element need not be determined or reported.

B. Designations established in accordance with Practice E527 and SAE J 1086.

C. For some applications, the substitution of Type 304L for Type 304, or Type 316L for Type 316 may be undesirable because of design, fabrication, or service requirements. In such cases, the purchaser should so indicate on the order.

D. UNS S31010 is a highly alloyed austenitic stainless steel type 3b as defined in NACE MR0175/ISO 15156-3.

E. Nitrogen content is to be reported for this grade.

F. % Cr + 3.3 × % Mo + 16 × % N $ 40.

G. Nickel plus copper shall be 0.50 % max.

H. Product analysis tolerance over the maximum limit for carbon and nitrogen shall be 0.002 %

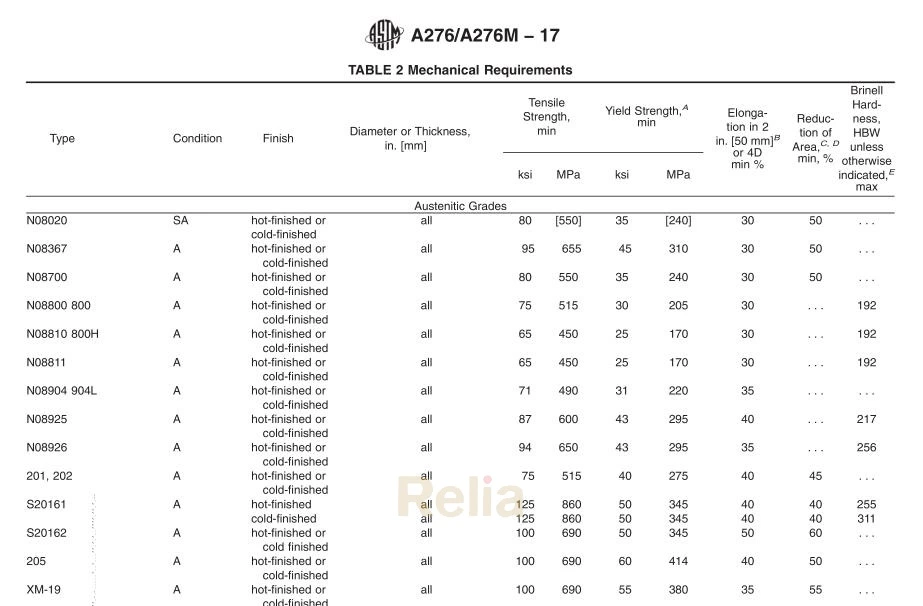

ASTM A276 Mechanical Properties

Note:

A. Yield strength shall be determined by the 0.2 % offset method in accordance with Test Methods and Definitions A370 or Test Methods A1058. An alternative method of determining yield strength may be used based on a total extension under load of 0.5 %.

B. For some specific products, it may not be practicable to use a 2-in. or 50-mm gage length. The use of sub-size test specimens, when necessary, is permissible inaccordance with Test Methods and Definitions A370 or Test Methods A1058.

C. Reduction of area does not apply on flat bars 3 ⁄ 1 6 in. [4.76 mm] and under in thickness as this determination is not generally made in this product size.

D. The material shall be capable of meeting the required reduction of area where listed, but actual measurement and reporting of the reduction of area are not required unless specified in the purchase order.

E. Or equivalent Rockwell hardness (HRB or HRC).

F. For extruded shapes of all Cr-Ni grades of Condition A, the yield strength shall be 25 ksi [170 MPa] min and tensile strength shall be 70 ksi [480 MPa] min.

G. For shapes having section thickness of 1 ⁄ 2 in. [12.5 mm] or less, 30% min. elongation is acceptable.

H. Material shall be capable of being heat treated to a maximum Brinell hardness of 250 HBW when oil quenched from 1750°F [950°C].