ASTM A352 Chemical Composition, Mechanical Properties

ASTM A352 specifies the chemical composition and mechanical properties of ASTM A352 materials, including ASTM A352 LCA, LCB, LCC, LC1, LC2, LC3, LC4, LC9, and CA6NM.

ASTM A352 covers steel castings for valves, flanges, fittings, and other pressure-containing parts intended primarily for low-temperature service.

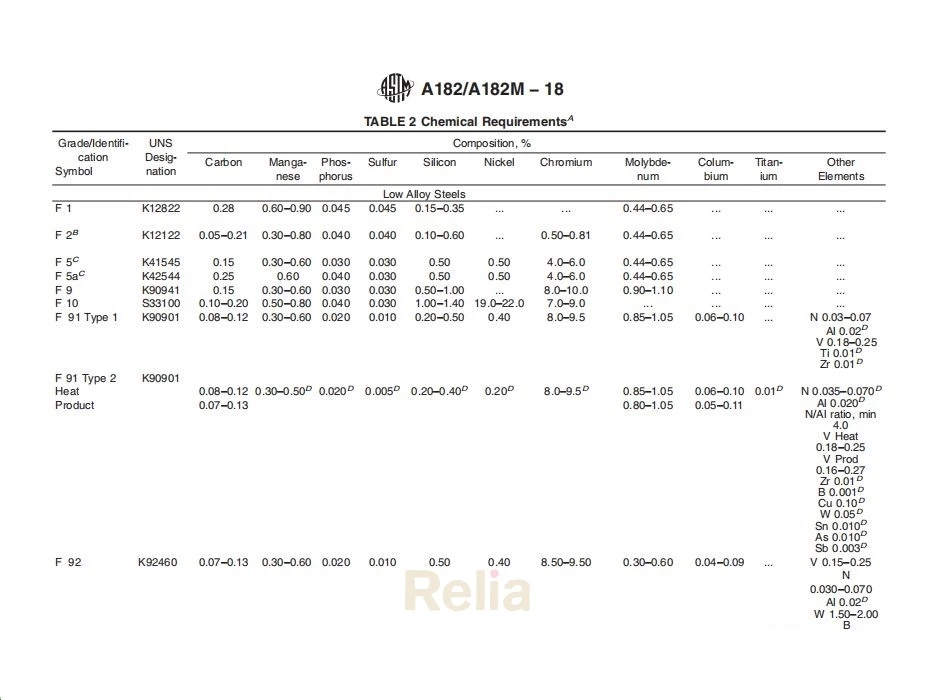

ASTM A352 Chemical Composition

| Material Grade UNS Type |

Composition, % | |||||||||

| Carbon | Manganese | Phosphorus | Sulfur | Silicon Nickel | Chromium | Molybdenum | Copper | Vanadium | ||

| LCAC J02504 Carbon Steel |

0.25 | 0.70 | 0.04 | 0.045 | 0.60 | 0.50D | 0.50D | 0.20 | 0.30 | 0.03D |

| LCBC J03003 Carbon Steel |

0.30 | 1.00 | 0.04 | 0.045 | 0.60 | 0.50D | 0.50D | 0.20D | 0.30D | 0.03D |

| LCCC J02505 C-Mn Steel |

0.25 | 1.20 | 0.04 | 0.045 | 0.60 | 0.50D | 0.50D | 0.20D | 0.30D | 0.03D |

| LC1 J12522 C-Mo Steel |

0.25 | 0.50-0.80 | 0.04 | 0.045 | 0.60 | ... | ... | 0.45-0.65 | ... | ... |

| LC2 J22500 2.5Ni Steel |

0.25 | 0.50-0.80 | 0.04 | 0.045 | 0.60 | 2.00-3.00 | ... | ... | ... | ... |

| LC2-1 J42215 Ni-Cr-Mo Steel |

0.22 | 0.55-0.75 | 0.04 | 0.045 | 0.50 | 2.50-3.50 | 1.35-1.85 | 0.30-0.60 | ... | ... |

| LC3 J31550 3.5Ni Steel |

0.15 | 0.50-0.80 | 0.04 | 0.045 | 0.60 | 3.00-4.00 | ... | ... | ... | ... |

| LC4 J41500 4.5Ni Steel |

0.15 | 0.50-0.80 | 0.04 | 0.045 | 0.60 | 4.00-5.00 | ... | ... | ... | ... |

| LC9 J31300 9Ni Steel |

0.13 | 0.90 | 0.04 | 0.045 | 0.45 | 8.50-10.0 | 0.50 | 0.20 | 0.30 | 0.03 |

| CA6NM J91540 12.5Cr-Ni-Mo Steel |

0.06 | 1.00 | 0.04 | 0.03 | 1.00 | 3.5-4.5 | 11.5-14.0 | 0.4-1.0 | ... | ... |

A All values are maximums unless a range is provided.

B Where “. . .” appears in this table, there is no requirement, and the element need not be analyzed for or reported.

C For each reduction of 0.01 % below the specified maximum carbon content, an increase of 0.04 % manganese above the specified maximum will be permitted up to a maximum of 1.10 % for LCA, 1.28 % for LCB, and 1.40 % for LCC.

D Specified Residual Elements—The total content of these elements is 1.00 % maximum.

ASTM A352 Mechanical Properties

| Material Grade | Tensile RequirementsA,B | Impact Requirements Charpy V-NotchB,E | |||||

| Tensile Strength, ksi [MPa] | Yield Strength,C ksi [MPa] | Elongation in 2 in. [50 mm], %D |

Reduction of Area, % | Minimum energy value for two specimens and minimum average of three specimens, ftJbf[J] |

Minimum energy value for single specimen, ft.lbf[J] | Testing Temperature, °F [°C] | |

| LCA J02504 Carbon Steel |

60.0-85.0 [415-585] |

30.0 [205] | 24 | 35 | 13 [18] | 10 [14] | -25 [-32] |

| LCB J03003 Carbon Steel |

65.0-90.0 [450-620] |

35.0 [240] | 24 | 35 | 13 [18] | 10 [14] | -50 [-46] |

| LCC J02505 C-Mn Steel |

70.0-95.0 [485-655] |

40.0 [275] | 22 | 35 | 15 [20] | 12 [16] | -50 [-46] |

| LC1 J12522 C-Mo Steel |

65.0-90.0 [450-620] |

35.0 [240] | 24 | 35 | 13 [18] | 10 [14] | -75 [-59] |

| LC2 J22500 2.5Ni Steel |

70.0-95.0 [485-655] |

40.0 [275] | 24 | 35 | 15 [20] | 12 [16] | -100 [-73] |

| LC2-1 J42215 Ni-Cr-Mo Steel |

105.0-130.0 [725-895] |

80.0 [550] | 18 | 30 | 30 [41] | 25 [34] | -100 [-73] |

| LC3 J31550 3.5Ni Steel |

70.0-95.0 [485-655] |

40.0 [275] | 24 | 35 | 15 [20] | 12 [16] | -150 [-101] |

| LC4 J41500 4.5Ni Steel |

70.0-95.0 [485-655] |

40.0 [275] | 24 | 35 | 15 [20] | 12 [16] | -175 [-115] |

| LC9 J31300 9Ni Steel |

85.0 [585] | 75.0 [515] | 20 | 30 | 20 [27] | 15 [20] | -320 [-196] |

| CA6NM J91540 12.5Cr-Ni-Mo Steel |

110.0-135.0 [760-930] |

80.0 [550] | 15 | 35 | 20 [27] | 15 [20] | -100 [-73] |

A All values are minimums unless a range is provided.

B See 1.2. C Determine by either 0.2 % offset method or 0.5 % extension-under-load method.

D When ICI test bars are used in tensile testing as provided for in Specification A703/A703M, the gage length to reduced section diameter ratio shall be 4 to 1.

E See Appendix X1.

Pressure Temperature Rating

ASTM A352 Gr. LCB (2), A352 Gr. LC1 (2), A217 Gr. WC1 (6)–(8)

Standard Class

| Temperature,°F | Working Pressures by Class, psig | ||||||

| 150 | 300 | 600 | 900 | 1500 | 2500 | 4500 | |

| -20 to 100 | 265 | 695 | 1,395 | 2,090 | 3,480 | 5,805 | 10,445 |

| 200 | 255 | 660 | 1,320 | 1,980 | 3,300 | 5,505 | 9,905 |

| 300 | 230 | 640 | 1,275 | 1,915 | 3,190 | 5,315 | 9,565 |

| 400 | 200 | 615 | 1,230 | 1,845 | 3,075 | 5,125 | 9,225 |

| 500 | 170 | 585 | 1,175 | 1,760 | 2,930 | 4,885 | 8,795 |

| 600 | 140 | 550 | 1,105 | 1,655 | 2,755 | 4,595 | 8,270 |

| 650 | 125 | 535 | 1,065 | 1,600 | 2,665 | 4,440 | 7,990 |

| 700 | 110 | 510 | 1,025 | 1,535 | 2,560 | 4,270 | 7,685 |

| 750 | 95 | 475 | 955 | 1,430 | 2,385 | 3,970 | 7,150 |

| 800 | 80 | 390 | 780 | 1,175 | 1,955 | 3,255 | 5,865 |

| 850 | 65 | 300 | 595 | 895 | 1,490 | 2,485 | 4,475 |

| 900 | 50 | 200 | 405 | 605 | 1,010 | 1,685 | 3,035 |

| 950 | 35 | 135 | 275 | 410 | 685 | 1,145 | 2,055 |

| 1,000 | 20 | 85 | 170 | 255 | 430 | 715 | 1,285 |

NOTES:

(1) Upon prolonged exposure to temperatures above 800°F, the carbide phase of steel may be converted to graphite. Permissible, but not recommended for prolonged use above 800°F.

(2) Only killed steel shall be used above 850°F.

(3) Not to be used over 700°F.

(4) Not to be used over 850°F.

(5) Not to be used over 500°F.

(6) Not to be used over 650°F.