ASTM A351 Chemical Compositions, Mechanical Properties

ASTM A351 specifies the chemical compositions and mechanical properties of ASTM A351 CF8M, CF3M, CF3, CF8, CF8C, CF10, CF10M,CG8M, CH8, CH10, CH20, CK20, CK3MCUN, CN3MN, and CN7M.

ASTM A351 covers austenitic steel castings for valves, flanges, fittings, and other pressure-containing parts.

ASTM A351 Chemical Compositions

| Material | Element, % (max, except where range is given) | ||||||||||

| Carbon | Mn | Silicon | Sulfur | Phos- phorus |

Chromium | Nickel | Moly- bdenum |

Columbium (Niobium)D |

Ni- trogen |

Copper | |

| CE20N | 0.20 | 1.50 | 1.50 | 0.040 | 0.040 | 23.0-26.0 | 8.0-11.0 | 0.50 | 0.08-0.20 | ||

| CF3, CF3A | 0.03 | 1.50 | 2.00 | 0.040 | 0.040 | 17.0-21.0 | 8.0-12.0 | 0.50 | |||

| CF8, CF8A | 0.08 | 1.50 | 2.00 | 0.040 | 0.040 | 18.0-21.0 | 8.0-11.0 | 0.50 | |||

| CF3M, CF3MA | 0.03 | 1.50 | 1.50 | 0.040 | 0.040 | 17.0-21.0 | 9.0-13.0 | 2.0-3.0 | |||

| CF8M | 0.08 | 1.50 | 1.50 | 0.040 | 0.040 | 18.0-21.0 | 9.0-12.0 | 2.0-3.0 | |||

| CF3MN | 0.03 | 1.50 | 1.50 | 0.040 | 0.040 | 17.0-21.0 | 9.0-13.0 | 2.0-3.0 | 0.10-0.20 | ||

| CF8C | 0.08 | 1.50 | 2.00 | 0.040 | 0.040 | 18.0-21.0 | 9.0-12.0 | 0.50 | A | ||

| CF10 | 0.04-0.10 | 1.50 | 2.00 | 0.040 | 0.040 | 18.0-21.0 | 8.0-11.0 | 0.50 | |||

| CF10M | 0.04-0.10 | 1.50 | 1.50 | 0.040 | 0.040 | 18.0-21.0 | 9.0-12.0 | 2.0-3.0 | |||

| CF10MC | 0.10 | 1.50 | 1.50 | 0.040 | 0.040 | 15.0-18.0 | 13.0-16.0 | 1.75-2.25 | B | ||

| CG3M | 0.03 | 1.50 | 1.50 | 0.04 | 0.04 | 18.0-21.0 | 9.0-13.0 | 3.040 | |||

| CG8M | 0.08 | 1.50 | 1.50 | 0.04 | 0.04 | 18.0-21.0 | 9.0-13.0 | 3.040 | |||

| CH8 | 0.08 | 1.50 | 1.50 | 0.040 | 0.040 | 22.0-26.0 | 12.0-15.0 | 0.50 | |||

| CH10 | 0.04-0.10 | 1.50 | 2.00 | 0.040 | 0.040 | 22.0-26.0 | 12.0-15.0 | 0.50 | |||

| CH20 | 0.04-0.20 | 1.50 | 2.00 | 0.040 | 0.040 | 22.0-26.0 | 12.0-15.0 | 0.50 | |||

| CK20 | 0.04-0.20 | 1.50 | 1.75 | 0.040 | 0.040 | 23.0-27.0 | 19.0-22.0 | 0.50 | |||

| CK3MCUN | 0.025 | 1.20 | 1.00 | 0.010 | 0.045 | 19.5-20.5 | 17.5-19.5 | 6.0-7.0 | 0.18-0.24 | 0.50-1.00 | |

| CN3MN | 0.03 | 2.00 | 1.00 | 0.010 | 0.040 | 20.0-22.0 | 23.5-25.5 | 6.0-7.0 | 0.18-0.26 | 0.75 | |

| CN7M | 0.07 | 1.50 | 1.50 | 0.040 | 0.040 | 19.0-22.0 | 27.5-30.5 | 2.0-3.0 | 3.0-4.0 | ||

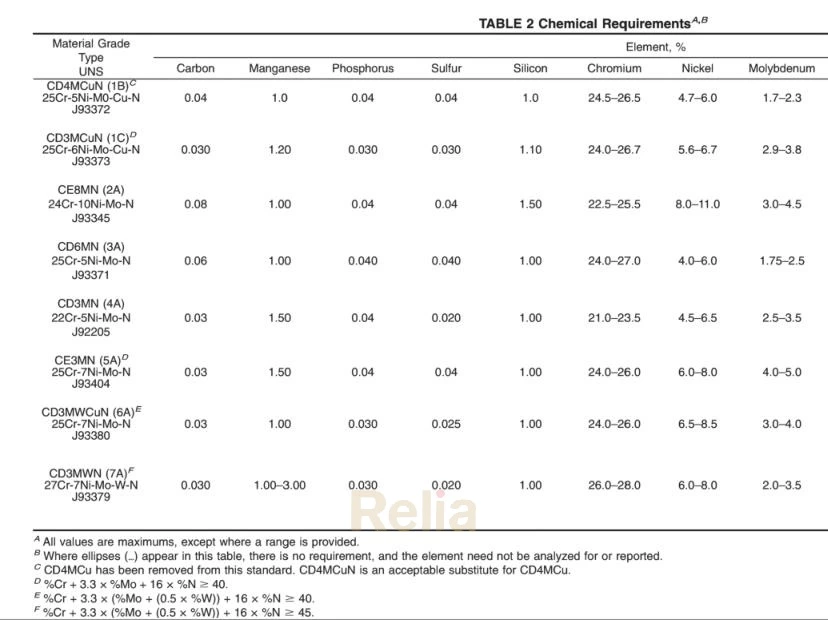

Note 1-CE8MN and CD3MWCuN have been deleted from this specification and added to Specification A995/A995M as Grades 2A and 6A, respectively. CD4MCu has also been removed. Specification A995/A995M Grade IB, CD4MCuN, is an acceptable substitute.

A Grade CF8C shall have a columbium (niobium) content of not less than 8 times the carbon content but not over 1.00 %.

B Grade CF10MC shall have a columbium (niobium) content of not less than 10 times the carbon content but not over 1.20 %.

C Grade HG10MnN shall have a columbium (niobium) content of not less than 8 times the carbon, but not over 1.00 %.

D Columbium (Cb) and niobium (Nb) are alternate names for Element 41.

ASTM A351 Mechanical Properties

| Material | Tensile strength, min, ksi [MPa] | Yield strength,A min, ksi [MPa] | Elongation in 2 in. or 50 mmB; min, % |

| CE20N | 80 [550] | 40 [275] | 30 |

| CF3 | 70 [485] | 30 [205] | 35 |

| CF3A | 77 [530] | 35 [240] | 35 |

| CF8 | 70 [485] | 30 [205] | 35 |

| CF8A | 77 [530] | 35 [240] | 35 |

| CF3M | 70 [485] | 30 [205] | 30 |

| CF3MA | 80 [550] | 37 [255] | 30 |

| CF8M | 70 [485] | 30 [205] | 30 |

| CF3MN | 75 [515] | 37 [255] | 35 |

| CF8C | 70 [485] | 30 [205] | 30 |

| CF10 | 70 [485] | 30 [205] | 35 |

| CF10M | 70 [485] | 30 [205] | 30 |

| CF10MC | 70 [485] | 30 [205] | 20 |

| CF10SMnN | 85 [585] | 42.5 [295] | 30 |

| CG3M | 75 [515] | 35 [240] | 25 |

| CG8M | 75 [515] | 35 [240] | 25 |

| CH8 | 65 [450] | 28 [195] | 30 |

| CH10 | 70 [485] | 30 [205] | 30 |

| CH20 | 70 [485] | 30 [205] | 30 |

| CK20 | 65 [450] | 28 [195] | 30 |

| CK3MCuN | 80 [550] | 38 [260] | 35 |

| CN3MN | 80 [550] | 38 [260] | 35 |

| CN7M | 62 [425] | 25 [170] | 35 |

A Determine by the 0.2 % offset method.

B When ICI test bars are used in tensile testing as provided for in Specification A995/A995M, the gauge length to reduced section diameter ratio shall be 4 to 1.