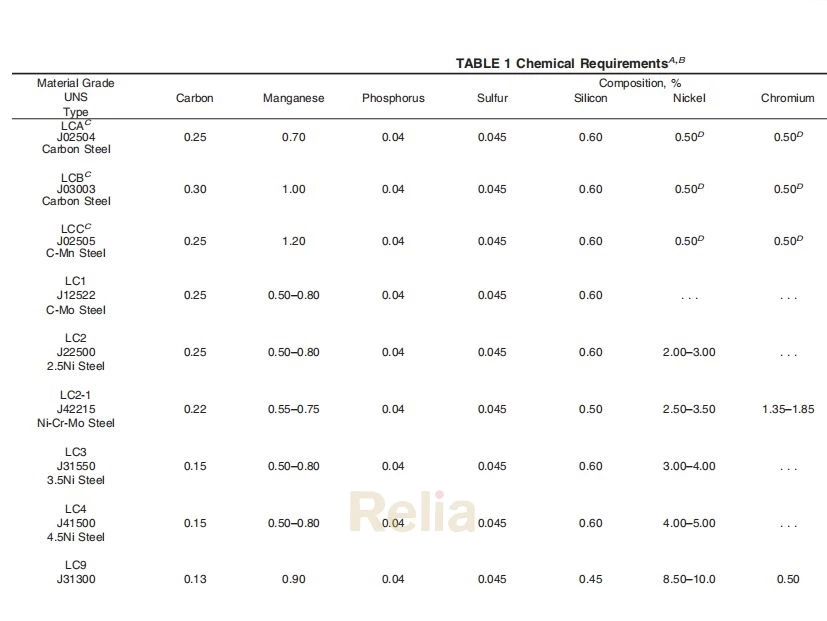

ASTM A182 Chemical Composition, Machemical Properties

ASTM A182 specifies the chemical composition and mechanical properties of ASTM F304, F316, F304L, F316L, FXM-19, F44, F321, F347, F45, F6A, F6, F9, F11, F51, F53, F55, and F60, etc.

ASTM A182 covers forged low alloy and stainless steel piping components for use in pressure systems, including flanges, fittings, valves, and similar parts.

ASTM A182 Chemical Composition

Low Alloy Steels

| Material | Composition, % | |||||||||||

| ASTM | UNS | Carbon | Manga -nese |

Phos -phorus |

Sulfur | Silicon | Nickel | Chromium | Moly-bdenum | Colum -bium |

Titan -ium |

Others |

| F5 | K41545 | 0.15 | 0.30-0.60 | 0.030 | 0.030 | 0.50 | 0.50 | 4.0-6.0 | 0.44-0.65 | |||

| F9 |

K90941

|

0.15 | 0.30-0.60 | 0.030 | 0.030 | 0.50-1.00 | ... | 8.0-10.0 | 0.90-1.10 | ... | ... | ... |

| F11 Class 1 |

K11597

|

0.05-0.15 | 0.30-0.60 | 0.030 | 0.030 | 0.50-1.00 | ... | 1.00-1.50 | 0.44-0.65 | ... | ... | ... |

| F11 Class 2 |

K11572

|

0.10-0.20 | 0.30-0.80 | 0.040 | 0.040 | 0.50-1.00 | ... | 1.00-1.50 | 0.44-0.65 | ... | ... | ... |

| F11 Class 3 |

K11572

|

0.10-0.20 | 0.30-0.80 | 0.040 | 0.040 | 0.50-1.00 | ... | 1.00-1.50 | 0.44-0.65 | ... | ... | ... |

ASTM A182 Chemical Compositions (Coniuned)

Martensitic Stainless Steels

| Material | Composition, % | |||||||||||

| ASTM | UNS | Carbon | Manga- anese |

Phos- phorus |

Sulfur | Silicon | Nickel | Chromium | Molybde- num |

Colum- bium |

Titan- ium |

Others |

| F 6a |

S41000

|

0.15 | 1.00 | 0.040 | 0.030 | 1.00 | 0.50 | 11.5-13.5 | ... | ... | ... | ... |

| F 6b |

S41026

|

0.15 | 1.00 | 0.020 | 0.020 | 1.00 | 1.00-2.00 | 11.5-13.5 | 0.40-0.60 | ... | ... | Cu 0.50 |

| F 6NM |

S41500

|

0.05 | 0.50-1.00 | 0.030 | 0.030 | 0.60 | 3.5-5.5 | 11.5-14.0 | 0.50-1.00 | ... | ... | ... |

ASTM A182 Chemical Compositions (Coniuned)

Austenitic Stainless Steels

| Material | Composition, % | |||||||||||

| ASTM | UNS | Carbon | Mang- anese |

Phos-

phorus

|

Sulfur | Silicon | Nickel | Chromium | Molybde- num |

Colum-

bium

|

Titan-

ium

|

Others |

| F 304 |

S30400

|

0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 8.0-11.0 | 18.0-20.0 | ... | ... | ... | N 0.10 |

| F 304H |

S30409

|

0.04-0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 8.0-11.0 | 18.0-20.0 | ... | ... | ... | ... |

| F 304L |

S30403

|

0.030 | 2.00 | 0.045 | 0.030 | 1.00 | 8.0-13.0 | 18.0-20.0 | ... | ... | ... | N 0.10 |

| F 304N |

S30451

|

0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 8.0-10.5 | 18.0-20.0 | ... | ... | ... | N 0.10-0.16 |

| F 316 |

S31600

|

0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 10.0-14.0 | 16.0-18.0 | 2.00-3.00 | ... | ... | N 0.10 |

| F 316H |

S31609

|

0.04-0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 10.0-14.0 | 16.0-18.0 | 2.00-3.00 | ... | ... | ... |

| F 316L |

S31603

|

0.030 | 2.00 | 0.045 | 0.030 | 1.00 | 10.0-15.0 | 16.0-18.0 | 2.00-3.00 | ... | ... | N 0.10 |

| F 316N |

S31651

|

0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0-14.0 | 16.0-18.0 | 2.00-3.00 | ... | ... | N 0.10-0.16 |

| F 316Ti |

S31635

|

0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 10.0-14.0 | 16.0-18.0 | 2.00-3.00 | ... | H | N 0.10 max |

| F 317 |

S31700

|

0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0-15.0 | 18.0-20.0 | 3.0-4.0 | ... | ... | ... |

| F 321 |

S32100

|

0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 9.0-12.0 | 17.0-19.0 | ... | ... | I | ... |

| F 347 |

S34700

|

0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 9.0-13.0 | 17.0-20.0 | ... | K | ... | ... |

| F XM-11 |

S21904

|

0.040 | 8.0-10.0 | 0.060 | 0.030 | 1.00 | 5.5-7.5 | 19.0-21.5 | ... | ... | ... | N 0.15-0.40 |

| F XM-19 |

S20910

|

0.06 | 4.0-6.0 | 0.040 | 0.030 | 1.00 | 11.5-13.5 | 20.5-23.5 | 1.50-3.00 | 0.10-0.30 | ... | N 0.20-0.40 V 0.10-0.30 |

| F 44 | S31254 | 0.020 | 1.00 | 0.030 | 0.010 | 0.80 | 17.5-18.5 | 19.5-20.5 | 6.0-6.5 | ... | ... | Cu 0.50-1.00 N 0.18-0.25 |

| F 45 | S30815 | 0.05-0.10 | 0.80 | 0.040 | 0.030 | 1.40-2.00 | 10.0-12.0 | 20.0-22.0 | ... | ... | ... | N 0.14-0.20 Ce 0.03-0.08 |

| F 904L | N08904 | 0.020 | 2.0 | 0.040 | 0.030 | 1.00 | 23.0-28.0 | 19.0-23.0 | 4.0-5.0 | ... | ... | Cu 1.00-2.00 |

ASTM A182 Chemical Compositions (Coniuned)

Ferritic-Austenitic Stainless Steels

| Material | Compositions, % | |||||||||||

| ASTM | UNS | Carbon | Mang- anese |

Phos- phorus |

Sulfur | Silicon | Nickel | Chromium | Moly- bdenum |

Colum- bium |

Titan- ium |

Other Elements |

| F51 | S31803 | 0.030 | 2.00 | 0.030 | 0.020 | 1.00 | 4.5-6.5 | 21.0-23.0 | 2.5-3.5 | ... | ... | N 0.08-020 |

| F53 | S32750 | 0.030 | 1.20 | 0.035 | 0.020 | 0.80 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 | ... | ... | N 024-0.32 Cu 0.50 |

| F55 | S32760 | 0.030 | 1.00 | 0.030 | 0.010 | 1.00 | 6.0-8.0 | 24.0-26.0 | 3.0-4.0 | ... | ... | N 020-0.30 Cu 0.50-1.00 W 0.50-1.00N |

| F60 | S32205 | 0.030 | 2.00 | 0.030 | 0.020 | 1.00 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 | ... | ... | N 0.14-020 |

ASTM A182 Machemical Properties

| Grade | Tensile Strength, min, ksi [MPa] |

Yield Strength, min,ksi [MPa]A |

Elongation in 2 in.B [50 mm] or 4D, min, % |

Reduction of Area, min, % |

Brinell Hardness Number, HBW, unless otherwise indicated |

| Low Alloy Steels | |||||

| F1 | 70 [485] | 40 [275] | 20 | 30 | 143-192 |

| F2 | 70 [485] | 40 [275] | 20 | 30 | 143-192 |

| F5 | 70 [485] | 40 [275] | 20 | 35 | 143-217 |

| F 5a | 90 [620] | 65 [450] | 22 | 50 | 187-248 |

| F9 | 85 [585] | 55 [380] | 20 | 40 | 179-217 |

| F10 | 80 [550] | 30 [205] | 30 | 50 | ... |

| F 91 Types 1 and 2 |

90 [620] | 60 [415] | 20 | 40 | 190-248 |

| F 92 | 90 [620] | 64 [440] | 20 | 45 | 269 max |

| F 93 | 90 [620] | 64 [440] | 19 | 40 | 250 max |

| F 122 | 90 [620] | 58 [400] | 20 | 40 | 250 max |

| F 911 | 90 [620] | 64 [440] | 18 | 40 | 187-248 |

| F 11 Class 1 | 60 [415] | 30 [205] | 20 | 45 | 121-174 |

| F 11 Class 2 | 70 [485] | 40 [275] | 20 | 30 | 143-207 |

| F 11 Class 3 | 75 [515] | 45 [310] | 20 | 30 | 156-207 |

| F 12 Class 1 | 60 [415] | 32 [220] | 20 | 45 | 121-174 |

| F 12 Class 2 | 70 [485] | 40 [275] | 20 | 30 | 143-207 |

| F 21 | 75 [515] | 45 [310] | 20 | 30 | 156-207 |

| F 3V, and F 3VCb | 85-110 [585-760] | 60 [415] | 18 | 45 | 174-237 |

| F 22 Class 1 | 60 [415] | 30 [205] | 20 | 35 | 170 max |

| F 22 Class 3 | 75 [515] | 45 [310] | 20 | 30 | 156-207 |

| F 22V | 85-110 [585-780] | 60 [415] | 18 | 45 | 174-237 |

| F 23 | 74 [510] | 58 [400] | 20 | 40 | 220 max |

| F 24 | 85 [585] | 60 [415] | 20 | 40 | 248 max |

| FR | 63 [435] | 46 [315] | 25 | 38 | 197 max |

| F 36, Class 1 | 90 [620] | 64 [440] | 15 | ... | 252 max |

| F 36, Class 2 | 95.5 [660] | 66.5 [460] | 15 | ... | 252 max |

| Martensitic Stainless Steels | |||||

| F 6a Class 1 | 70 [485] | 40 [275] | 18 | 35 | 143-207 |

| F 6a Class 2 | 85 [585] | 55 [380] | 18 | 35 | 167-229 |

| F 6a Class 3 | 110 [760] | 85 [585] | 15 | 35 | 235-302 |

| F 6a Class 4 | 130 [895] | 110 [760] | 12 | 35 | 263-321 |

| F 6b | 110-135 [760-930] | 90 [620] | 16 | 45 | 235-285 |

| F 6NM | 115 [790] | 90 [620] | 15 | 45 | 295 max |

| Ferritic Stainless Steels | |||||

| F XM-27Cb | 60 [415] | 35 [240] | 20 | 45 | 190 max |

| F 429 | 60 [415] | 35 [240] | 20 | 45 | 190 max |

| F 430 | 60 [415] | 35 [240] | 20 | 45 | 190 max |

| Austenitic Stainless Steels | |||||

| F 304 | 75 [515]C | 30 [205] | 30 | 50 | ... |

| F 304H | 75 [515]C | 30 [205] | 30 | 50 | ... |

| F 304L | 70 [485]D | 25 [170] | 30 | 50 | ... |

| F 304N | 80 [550] | 35 [240] | 30E | 50F | ... |

| F 304LN | 75 [515]C | 30 [205] | 30 | 50 | ... |

| F 309H | 75 [515]C | 30 [205] | 30 | 50 | ... |

| F 310 | 75 [515]C | 30 [205] | 30 | 50 | ... |

| F 310MoLN | 78 [540] | 37 [255] | 25 | 40 | ... |

| F 310H | 75 [515]C | 30 [205] | 30 | 50 | ... |

| F 316 | 75 [515]C | 30 [205] | 30 | 50 | ... |

| F 316H | 75 [515]C | 30 [205] | 30 | 50 | ... |

| F 316L | 70 [485]D | 25 [170] | 30 | 50 | ... |

| F 316N | 80 [550] | 35 [240] | 30E | 50F | ... |

| F 316LN | 75 [515]C | 30 [205] | 30 | 50 | ... |

| F 316Ti | 75 [515] | 30 [205] | 30 | 40 | ... |

| F 317 | 75 [515]C | 30 [205] | 30 | 50 | ... |

| F 317L | 70 [485]D | 25 [170] | 30 | 50 | ... |

| F 72 | 80 [550] | 36 [245] | 35 | 50 | 217 |

| F 73 | 93 [640] | 43 [295] | 40 | 50 | 217 |

| F 347 | 75 [515]C | 30 [205] | 30 | 50 | ... |

| F 347H | 75 [515]C | 30 [205] | 30 | 50 | ... |

| F 347LN | 75 [515] | 30 [205] | 30 | 50 | ... |

| F 348 | 75 [515]C | 30 [205] | 30 | 50 | ... |

| F 348H | 75 [515]C | 30 [205] | 30 | 50 | ... |

| F 321 | 75 [515]C | 30 [205] | 30 | 50 | ... |

| F 321H | 75 [515]C | 30 [205] | 30 | 50 | ... |

| F XM-11 | 90 [620] | 50 [345] | 45 | 60 | ... |

| FXM-19 | 100 [690] | 55 [380] | 35 | 55 | ... |

| F 20 | 80 [550] | 35 [240] | 30 | 50 | ... |

| F 44 | 94 [650] | 44 [300] | 35 | 50 | ... |

| F 45 | 87 [600] | 45 [310] | 40 | 50 | ... |

| F46 | 78 [540] | 35 [240] | 40 | 50 | ... |

ASTM A182 Machemical Properties (Continued)

| Grade | Tensile Strength, min, ksi [MPa] | Yield Strength, min, ksi [MPa]B | Elongation in 2 in. [50 mm] or 4D, min, % |

Reduction of Area, min, % | Brinell Hardness Number, HBW, unless otherwise indicated |

| F 47 | 75 [525] | 30 [205] | 40 | 50 | ... |

| F 48 | 80 [550] | 35 [240] | 40 | 50 | ... |

| F 49 | 115 [795] | 60 [415] | 35 | 40 | ... |

| F 56 | 73 [500] | 27 [185] | 30 | 35 | ... |

| F 58 | 109 [750] | 61 [420] | 35 | 50 | ... |

| F 62 | 95 [655] | 45 [310] | 30 | 50 | ... |

| F 63 | 80 [550] | 32 [220] | 25 | ... | 192 max |

| F 64 | 90 [620] | 40 [275] | 35 | 50 | 217 max |

| F70 | 70 [480] | 25 [175] | 35 | ... | HRB 90 max |

| F 904L | 71 [490] | 31 [215] | 35 | ... | ... |

| Ferritic-Austenitic Stainless Steels | |||||

| F 50 | 100-130 [690-900] | 65 [450] | 25 | 50 | ... |

| F 51 | 90 [620] | 65 [450] | 25 | 45 | … |

| F 52 | 100 [690] | 70 [485] | 15 | ... | ... |

| F53# 2in. [50 mm]G | 116 [800] | 80 [550] | 15 | ... | 310 max |

| F53>2in. [50 mm]G | 106 [730] | 75 [515] | 15 | ... | 310 max |

| F 54 | 116 [800] | 80 [550] | 15 | 30 | 310 max |

| F 55 | 109-130 [750-895] | 80 [550] | 25 | 45 | ... |

| F 57 | 118 [820] | 85 [585] | 25 | 50 | ... |

| F 59 | 112 [770] | 80 [550] | 25 | 40 | ... |

| F 60 | 95 [655] | 65 [450] | 25 | 45 | ... |

| F 61 | 109 [750] | 80 [550] | 25 | 50 | ... |

| F 65 | 109 [750] | 80 [550] | 25 | ... | ... |

| F 66 | 94 [650] | 65 [450] | 30 | ... | 290 max |

| F 67 | 90 [620] | 65 [450] | 18 | ... | 302 |

| F 68 | 87 [600] | 58 [400] | 25 | ... | 290 max |

| F 69 | 94 [650] | 65 [450] | 30 | ... | ... |

| F 71 | 101 [700] | 72 [500] | 15 | ... | 321 |

A Where ellipses appear in this table, there is no requirement and the test for the value need neither be performed nor a value reported.

B< Determined by the 0.2 % offset method. For ferritic steels only, the 0.5 % extension-under-load method may also be used.

C For sections over 5 in. [130 mm] in thickness, the minimum tensile strength shall be 70 ksi [485 MPa].

D For sections over 5 in. [130 mm] in thickness, the minimum tensile strength shall be 65 ksi [450 MPa].

E Longitudinal. The transverse elongation shall be 25 % in 2 in. or 50 mm, min.

F Longitudinal. The transverse reduction of area shall be 45 % min.

G Maximum section thickness at the time of heat treatment; see 7.4.